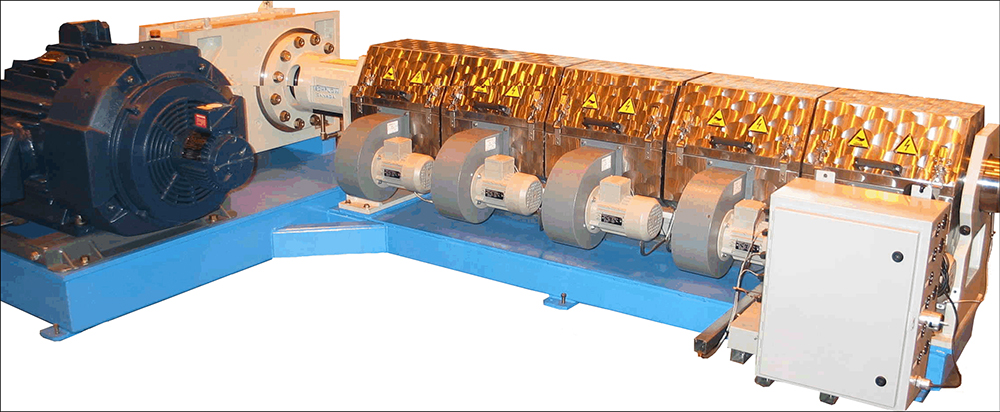

The extruder screw is the single most important component in your line that can vastly improve profitability. Barrier screws are often designed on a “trial & error” basis without taking into account the rheological nature of the polymers being processed. This results in inefficient screws that lag behind those that are properly designed. An efficient & productive screw will pay for itself in performance gains. The capital investment involved in purchasing a new high performance barrier screw is minimal when compared to the savings you will receive through the added process improvements, justifying the cost.

Extruders

Barrier ScrewsExtruder Barrier Screw Some screws perform one of the below tasks adequately, and the others below acceptable standards. A screw that is well suited to your application will satisfy your requirement for these parameters. Any one of these parameters that limit your operation is limiting your profitability. With this in mind it is easy to justify investing in a new TechFlow screw and barrel. Optimize your profitability by optimizing each of these parameters, consider upgrading your extrusion line with a new Techflow extruder screw and barrel. You will be pleasantly surprised with the cost!

- Throughput rate

- Melt temperature and temperature uniformity

- Spiral or straight Maddock mixing section for dispersive mixing

- Melt quality and mixing uniformity

- Stability of output, pressure and temperature

- Power consumption